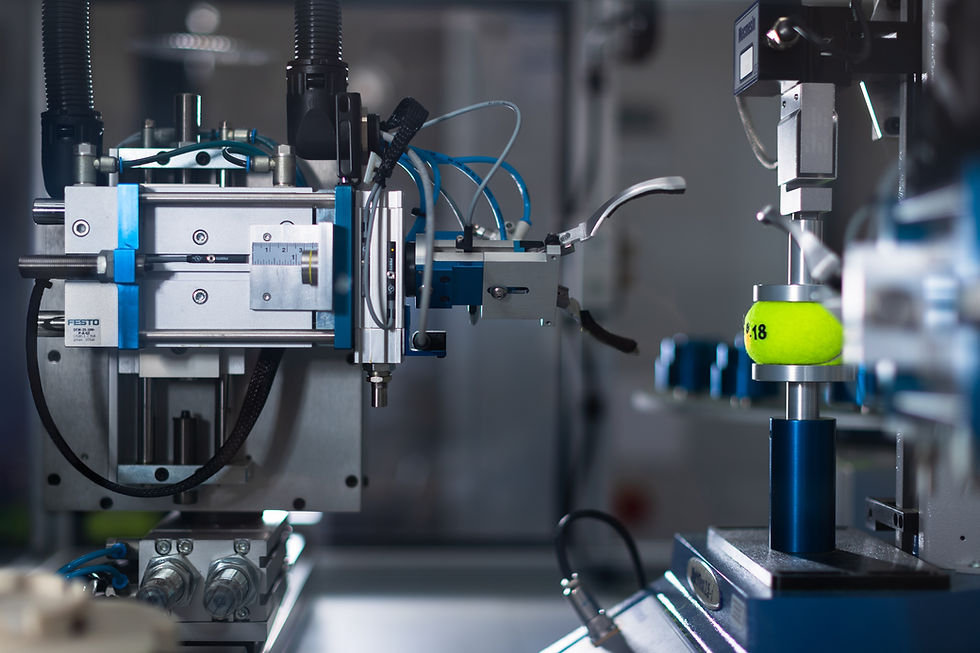

PRECISION ENGINEERING

Strong Foundation for Growth

The global precision parts market by revenue is expected to grow at a CAGR of over 10% during the period 2019-2025.

Source: Business Wire, Global Precision Parts Market Outlook and Forecast 2020-2025.

Digitalization Era

Industries across the world are witnessing a shift to digitalization in the production line. Factories are no longer run at the surface level, but they need to collect data from different sensors to measure throughput, and systems need to provide analysis in real-time and controls for optimized performance.

Optimize business operations and processes with Arcstone's enhanced Production Traceability toolsets.

Production Traceability and Inventory Management for your Factory Floor

Real-time Monitoring and Tracking for Greater Visibility and Control

-

Improved capabilities to track and trace materials, energy, labor, and other inputs during the production process

-

Meet quality compliance standards and raw material audits even under the strictest requirements

-

Toolsets integrated with barcode and RFID scanning to track your raw material usage

-

Real-time production floor visibility allowing full manufacturing overview for owners and management

-

Monitor production progress and performance with custom dashboards and reports

-

Alarms and alerts for immediate and preventive action

Data-driven Production Traceability

Realize step change improvements in safety and value creation with arc.ops

arc.ops offers

Traceability

-

Improved capabilities to track and trace materials, energy, labor, and other inputs during the production process

-

The meeting of quality compliance standards and raw material audits even under the strictest requirements

-

Toolsets integrated with barcode and RFID scanning to track your raw material usage

-

Auto-scheduling of jobs based on available qualified personnel, machines and resources

arc.ops offers

Machine Integration

-

Our arc.quire Data Acquisition System can pull streams of data from production floors, allowing for real-time monitoring and control of operations

-

Arcstone's arc.link system integrates existing software solutions, so manufacturers can centralize core data into specific databases

-

Custom alerts and triggering of new workflows when machines or resources are unavailable

arc.ops offers

Quality

-

Improved safety tracking and updates for Quality Assurance (QA) status

-

Digitalized Production Processes to improve input, tracking and monitoring of data related to QA

-

Full inventory control to identify low inventory levels and provide full visibility and control

-

Customized quality control processes with flexible digital checklists and e-signatures